Commodities

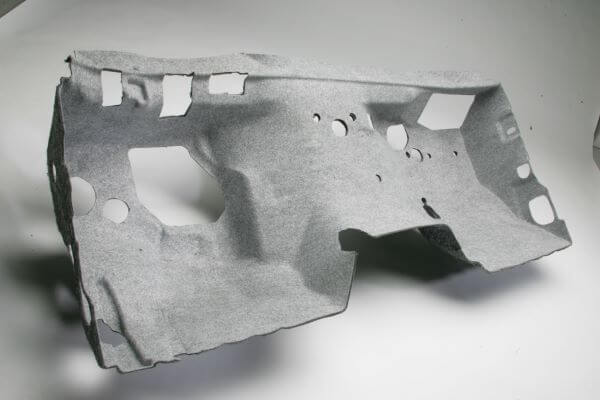

- LIGHTWEIGHT DASH INSULATORS

- LIGHTWEIGHT ACCESSORIES

- BODY PANELS

- LIGHTWEIGHT HEATSHIELDS

- STRUCTURAL PARTS

- WHEEL LINERS

- CARPETS

- HEADLINERS

- BATTERY COVERS

Materials and Composites

- KEVLAR

- AZDEL

- PET (POLYETHELENE TEREPHTALATE

- GMT (GLASS MAT THERMOPLASTIC)

- EVA (ETHYLENE VINYL ACETATE)

- INSULATION/ FOIL

- S-GLASS

- E-GLASS

- SMC- SHEET MOLDED COMPOUND

- CHOPPED CARBON FIBER

- CARBON FIBER PRE-PREG

RCO Engineering: Compression Molding Services

Our teams of compression molding specialists use advanced equipment to create components of various sizes, weights, and materials for projects of all sizes, from a few prototypes to large-run production jobs.

Our compression molding equipment is constantly at work creating numerous products including: lightweight fiber dash insulators, molded cargo management systems, trunk trims, cast foam dash insulators, and others.

Who Needs Compression Molding Services?

Compression molding services are an ideal process for large, complex parts that require high strength and stiffness. The compression molding process can be used to mold parts with a wide range of size, shapes, and complexity. Compression molded composites are also known for their superior dimensional stability, making them ideal for applications where close tolerance is required.

Compression molding tooling is typically less expensive than tooling for other processes and can be quickly produced. Our team of compression molding experts has the experience and knowledge to produce high-quality, complex parts quickly and efficiently.

Compression Molding Processes

RCO Engineering offers a wide range of custom compression mold manufacturing services. Our team is not limited to any one compression molding process; instead, we are able to leverage our experience and capabilities of different molds through the use of compression mold tooling that allows us to be more flexible in our approach. We can take an injection molded part or assembly and encapsulate it into a high-pressure core-shell molding process with excellent results.

- HEATED COMPRESSION MOLDING

- COLD COMPRESSION MOLDING

- THERMOFORM

- COMPRESSION LAMINATION

- COMPRESSION MOLD TOOLING

Other Molding Processes

We also offer injection molding services which differ from compression molding in that plastic is melted and injected into a molding tool. This process is commonly used to produce small-to-mid-sized orders of plastic components

RCO Engineering is a compression molding company, so you can trust that our compression molding engineers and designers have extensive experience taking traditional sheet metal or aluminum components and redesigning them as lightweight composite components. Often times we are able to take an assembly with 20 different part numbers and compression mold it as a single finished component. Our team of compression mold manufacturers have begun to mold in complex ribs and attachments for cost and weight savings while completely eliminating the need for secondary assembly.