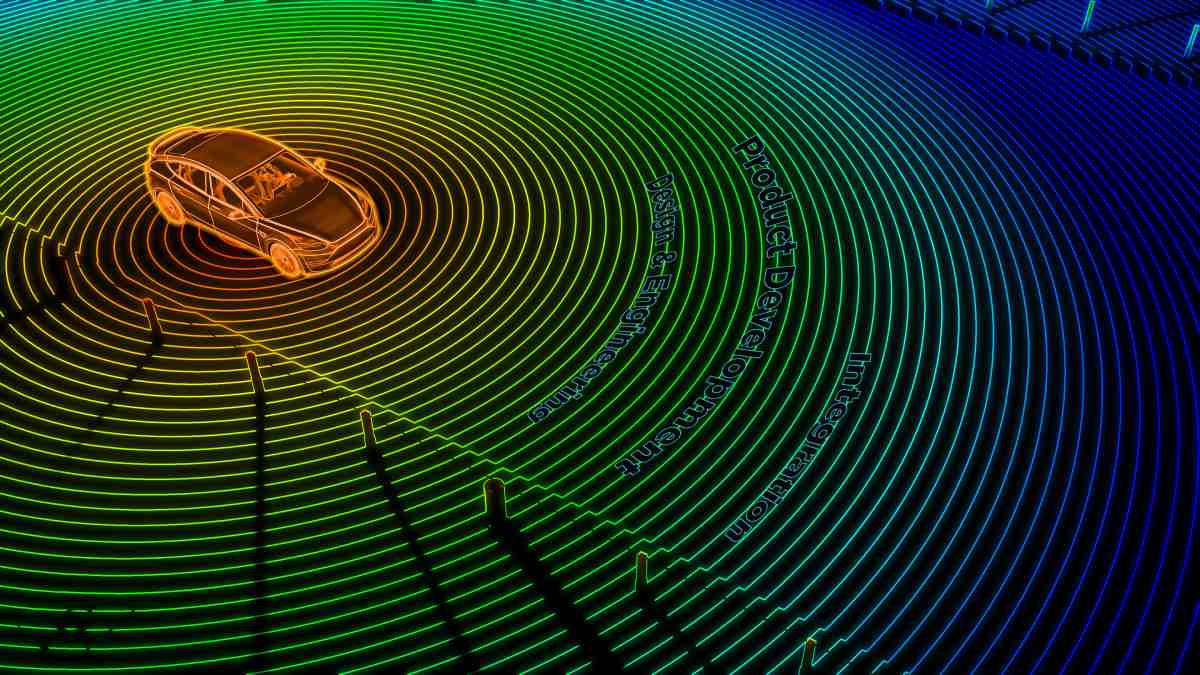

RCO Engineering offers a full spectrum of manufacturing product development services, making us a premier product development company.

Our comprehensive product development services include everything from the initial concept design to final assembly. With everything managed under one umbrella, we have an integrated approach that simplifies the process. This gives us a better system for managed modifications as needed and improving quality of end-products. By overseeing the entire process, we ensure continuity and consistent outcomes for clients.

Prototype Development for Innovative Companies

We specializing in prototype development and low-volume orders. Our expert team has the flexibility and expertise to produce a wide range of items tailored to specific needs. Our prototype development services are essential for design for manufacturing, allowing us to refine and optimize products before full-scale production begins.

This stage allows us to:

- identify potential issues

- make changes based on user feedback

- ensure quality end products

Our product development process is meticulous, ensuring every product meets our high standards and your specifications. If you want to expand your product line, our expert team can bring your vision to life with precision and efficiency.

Product Design for Manufacturing

At RCO Engineering, we use advanced manufacturing to provide superior product design and development services, including:

-

CNC Machining

Ideal for precise and repeatable manufacturing for complex designs, and efficient for both prototypes and mass production. It accommodates a wide variety of materials including metals and plastics. -

Injection Molding

Provides consistent quality and supports a broad range of materials and color options. Efficient for mass production of durable and strong parts. -

Metal Stamping

Delivers high precision and unparalleled durability for metal components. This technique utilizes specialized dies and presses to shape and form metal sheets into intricate parts that meet the tightest of tolerances. This level of accuracy translates to superior performance and reliability in the final product. -

Molding Milled Foam

Suitable for rapid prototyping and part production. Its ability to capture intricate contours and maintain a lightweight construction makes it an ideal solution for a wide range of applications, from automotive to aerospace. The precision of milled foam allows for the creation of highly detailed parts, enabling the exploration of complex geometries and the refinement of intricate design features.

Bring Your New Products to Life

Choose RCO Ean just a service provider. RCO Engineering is your partner in bringing your new product to market with our ptoduct develoment services. Our team of experts works closely with you to understand your specific needs and challenges, ensuring personalized service and tailored solutions.