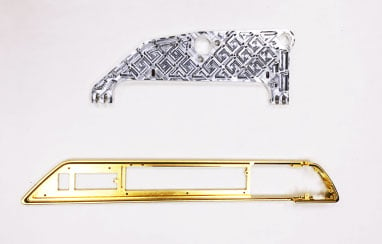

We deliver specialized and highly customized aerospace engineering services with the efforts and dedication of over 300 engineers and designers experienced in plastic, metal, and composite product design.

Our team has designed 4 families, with 25 different model numbers, of TSOA seats and divans that are in service today.